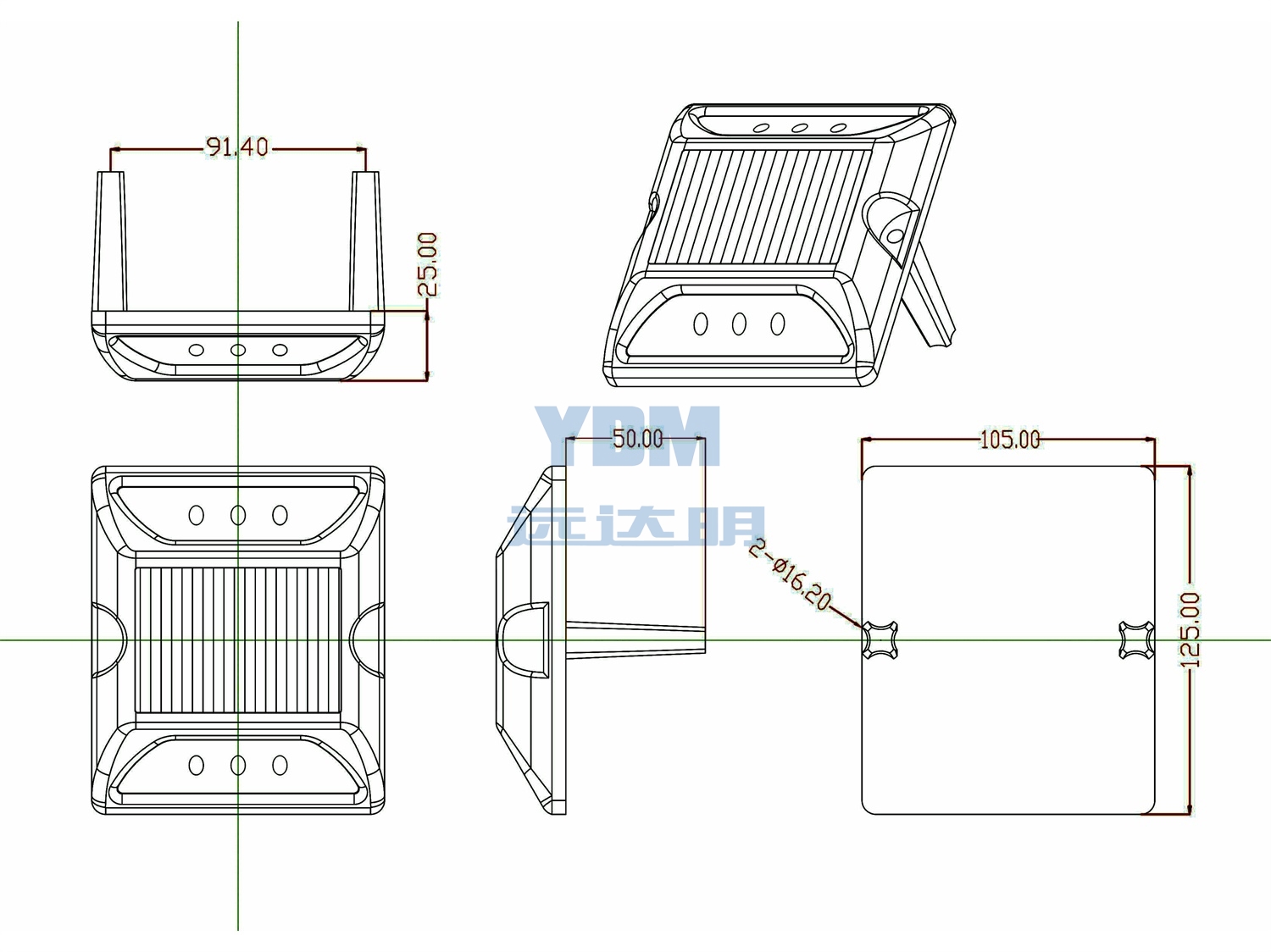

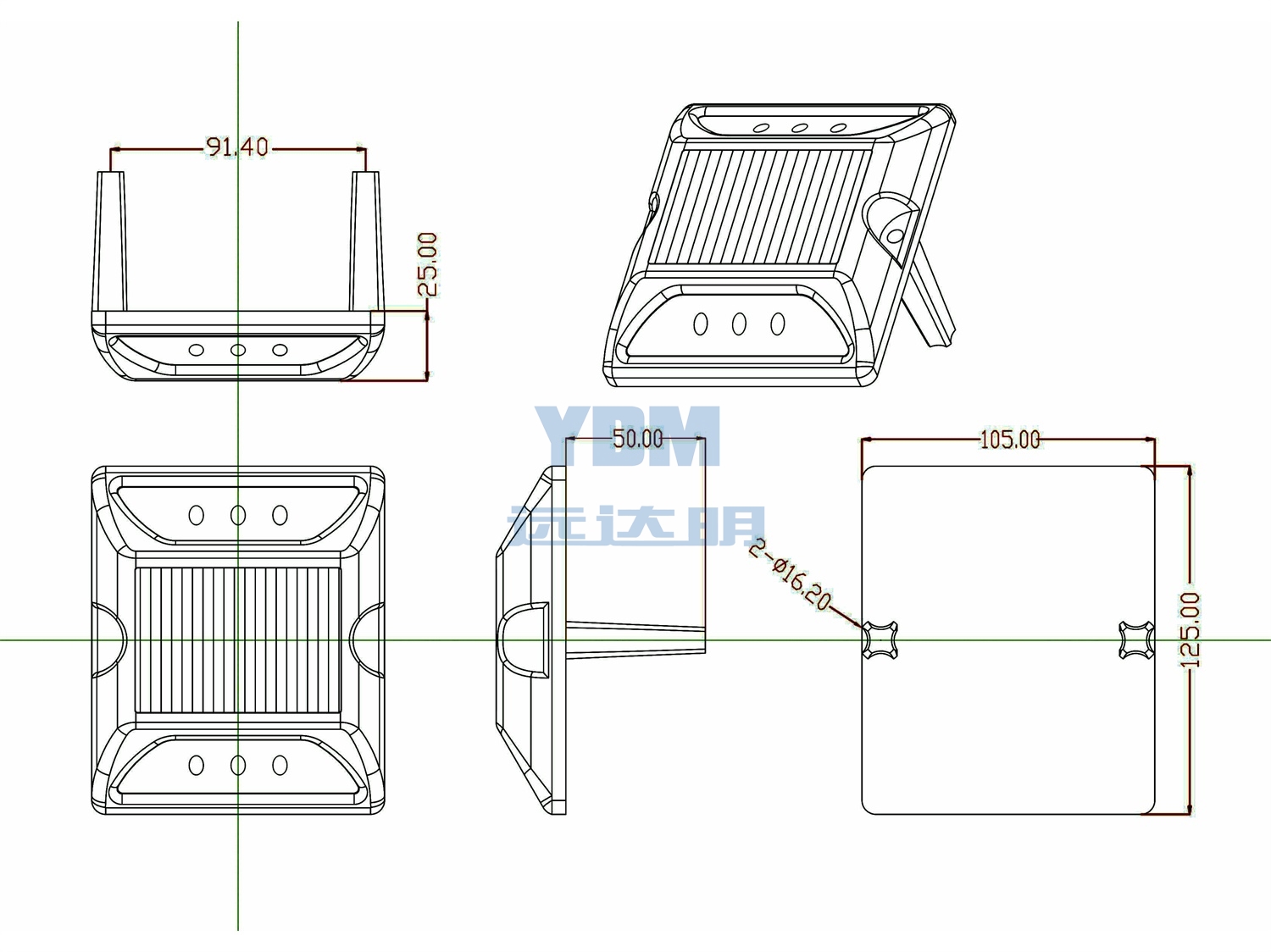

Solar road stud with two shanks 125

RSAS-F1-2L , RSAS-F1-2L3 (one way) -F(Flash) -S(Steady)

RSAS-F2-2L , RSAS-F2-2L3 (two way) -F(Flash) -S(Steady)

Key Features:

Flexible solar panel,

20ton compression resistance.

Larger solar charging area.

Anti-impact and IP68 design for reflector.

with two shanks, without releasing on road

-

-

Size125x105x25mm

-

Shank Sizelength: 50 mm

-

Net Weight0.45kg

-

MaterialAluminum alloy shell+Polycarbonate+epoxy filler

-

LEDφ5mm, one-way 2pcs or 3pcs, two-way 4pcs or 6pcs

-

LED Working ModeSteady or Flash (2HZ or upon request)

-

Luminous intensity5000mcd

-

View distanceover 500m

-

ColorRed/Yellow/White/Blue/Green

-

Solar PanelFlexible solar panel 2V 120MA

-

BatteryNI-MH battery /1.2V 1200MAH

-

Battery Life spanMore than 3 years

-

Charge time8 hours @100 Klux(sunny day)

-

Working time72 hours

-

Activationphoto sensor

-

Starting intensity500Lux

-

Compression resistanceover 20 tons

-

Working temperature-20℃~+70℃

-

Ingress ProtectionIP68

-

WarrantyOne year

-

-

Installation:

1. Before installation, solar road studs shall be charged under sunlight for 1 hr, to check the studs can work normally.

2. Placing security isolation facilities for installation work is most important and must not be ignored. In the whole process of dynamic construction, no matter in an new closed road or a running road, every installers shall be in the isolation area. If in a running road, the ratio between security personnel and the installing personnel shall be 1:1; If in a closed road, 1:3.

3. Locate the installing position and ensure it is flat. For curving, cracked or uneven pavement, straighten it prior to installation.

4. Clean the installation location with a brush, meanwhile ensure the location is dry.

5. Glue the road stud thoroughly with proper amount of epoxy glue.

6. Firmly mount the stud on the fixing location & ensure the reflective part is facing the right traffic direction. Do clean the spilled epoxy glue if excessive amount is used.

7. Inspect the installed studs within 2hrs after installation, ensuring that all the studs are fixed in correct direction or not crooked.

8. Remove the isolation facilities in 4hrs after the stud’s installing glue is thoroughly cured.Application:

• Road Delineation

• Accident black-spots / cluster sites

• Hazardous road layouts

• Areas adversely affected by poor visibility

• Cycle path

• Car parksCarton:

61*33*30cm GW:450g/pc NW: 450g/pc 60pcs/carton

-

Item No.:

RSAS-F1-2L , RSAS-F1-2L3 (one way) -F(Flash) -S(Steady)

RSAS-F2-2L , RSAS-F2-2L3 (two way) -F(Flash) -S(Steady)

Key Features:

Flexible solar panel,

20ton compression resistance.

Larger solar charging area.

Anti-impact and IP68 design for reflector.

with two shanks, without releasing on road